As automotive innovation accelerates, the need to create reliable and accurate modelling and simulation grows. This is where an Empirical Digital Twin (EDT) - a digital replica of a physical object – can add a huge amount of value to the development process. In this case study we’ll discuss the benefits of creating an EDT for a powertrain, that is derived from actual data and validated against real test results. OEMs rely on these powerful digital tools for trustworthy simulated results that help them optimize verification, validation, and sign-off processes and ensure that the vehicles they deliver to consumers meet and exceed industry standards. These digital replicas also provide a clear record of simulated events for future reference by an OEM’s legal team should problems occur.

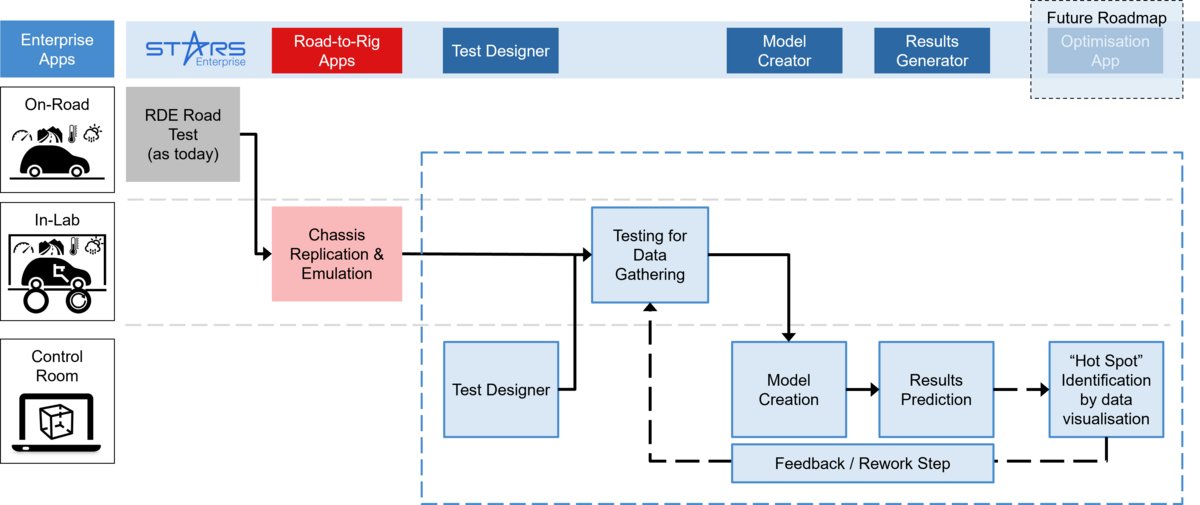

The following case study explores how an Empirical Digital Twin of a powertrain system is used as part on an OEM’s existing sign-off process using our STARS Test Automation and STARS Enterprise software.

Today’s engineers are being told to increase legislative coverage without increasing the time and resources dedicated to the validation and sign-off phase of vehicle development. This has proven to be a significant challenge. Traditional lab-based and in-field testing often does not provide a comprehensive understanding of a vehicle’s performance under the full range of conditions imposed by some regulations, such as RDE. By replicating a real powertrain system with a test data defined model, engineers can predict areas of non-conformity that may otherwise go unnoticed until a vehicle reaches the end consumer.

In the context of complex, non-linear systems such as hybrid powertrains, thermal systems, and fuel cells, Empirical Digital Twins capture nuanced behavior that may be challenging or onerous to replicate by physical testing or via physics-based models. By enabling quick, precise, and scalable model creation, these replicas significantly enhance the sign-off process and offer a holistic and efficient approach to verifying and validating vehicle performance.

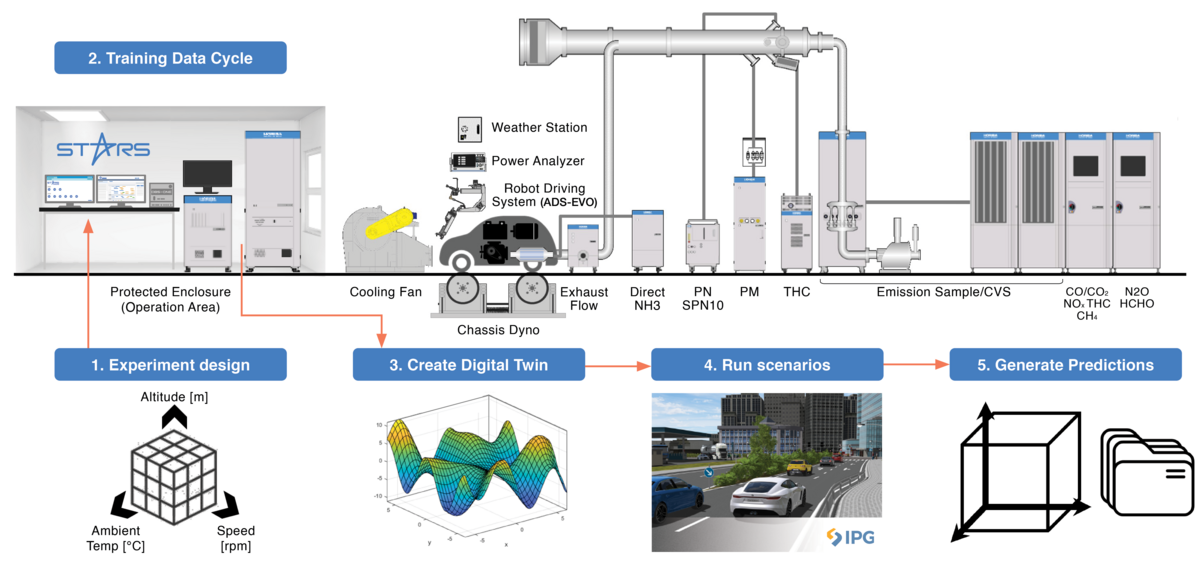

The process began by taking a vehicle supplied by the internal customer, typically for verification and sign-off (e.g. the vehicle project team) and preparing it with minimum instrumentation as well as the addition of an automatic driving robot. We used the ADS EVO.

Before the dynamic designs could be created, prior information on vehicle performance was required. The OEM operated the test vehicle over WLTPs, several RDE cycles (gentle to aggressive), and customer specific cycles logging engine rotational speed, vehicle velocity, pedal positions (where possible) and gear number. Emissions were not required at this point. This data would be used to help define the transient behavior of the dynamic designs i.e. rates of vehicle velocity change and rates of pedal change. In addition, it will allow constraints to be applied to the dynamic designs so not to exercise the test vehicle in an unfavorable manner. Before the dynamic designs can be created, prior information on vehicle performance is required.

Before the dynamic designs could be created, prior information on vehicle performance was required. The OEM operated the test vehicle over WLTPs, several RDE cycles (gentle to aggressive), and customer specific cycles logging engine rotational speed, vehicle velocity, pedal positions (where possible) and gear number. Emissions were not required at this point. This data would be used to help define the transient behavior of the dynamic designs i.e. rates of vehicle velocity change and rates of pedal change. In addition, it will allow constraints to be applied to the dynamic designs so not to exercise the test vehicle in an unfavorable manner. Before the dynamic designs can be created, prior information on vehicle performance is required.

Once the information from the previous step was gathered, our Test Design Tool was used to develop sufficiently dynamic designs for the chassis dyno to run based on the desired design space exploration requirements. The input parameters to the designs were vehicle velocity, accelerator and brake pedal position.

The chassis dynamometer was operated in speed/pedal mode with the dyno controlling vehicle velocity and the ADS-EVO robot driver controlling pedal positions. The vehicle was kept in the most appropriate gear and vehicle performance across its full operational range and data was captured.

STARS VETS was used to cascade the dynamic designs of vehicle velocity and accelerator pedal position to the chassis dynamometer and robot driver control systems respectively. Vehicle and powertrain performance emissions were recorded using STARS VETS.

Vehicle and powertrain performance emissions were recorded using STARS VETS. This recorded data (training data) was then used to create empirical models of various performance and emissions attributes per gear.

Validation test cycles were required to determine model quality. These took the form of customer specific cycles (for example RDE cycles for which pre-existing results existed) which needed to be run on the same day as the dynamic designs.

Once the model accuracy was validated the digital twin model was then used with  software (MAtLab Simulink would have also been sufficient) to predict performance and emissions across thousands of scenarios at faster than real time. A standard file defining the simulated criteria was created based on real-world cycles and theoretical worst-case cycles. Using this file significantly reduced physical testing times associated with gaining the coverage needed to confidently put the vehicle into production.

software (MAtLab Simulink would have also been sufficient) to predict performance and emissions across thousands of scenarios at faster than real time. A standard file defining the simulated criteria was created based on real-world cycles and theoretical worst-case cycles. Using this file significantly reduced physical testing times associated with gaining the coverage needed to confidently put the vehicle into production.

Visit IPG CarMaker for more information on the software used in this case study.

The simulation predictions highlighted problematic areas within a few minutes given how quickly the simulation was executed. This information was then passed to the vehicle team for rapid and targeted problem-resolution actions. Once all areas of the regulatory map were clear, this information was presented to the vehicle program team and the legal team for review and sign-off.

Empirical Digital Twin Creation Process: Using a Chassis Dynamometer

If possible, the following should be available for recording during the dynamic design tests. Only the robot driver and automation system parameters are required during the preliminary testing.

Gaseous engine out emissions

Gaseous engine out emissions

All the above should be logged in STARS VETS at between 1Hz and 10Hz (preferred).

The testing undertaken by HORIBA MIRA employees took 2 days; 1 day for setup and preliminary testing, and 1 day to deploy the dynamic designs and complete the validation cycles. Contingency for 1 additional day would be recommended.

Below is a summary of the roles and responsibilities:

Test cell setup | HORIBA UK and Customer |

Preliminary testing | HORIBA UK and Customer |

| Dynamic design deployment | HORIBA MIRA |

| Validation cycle deployment | HORIBA MIRA |

| Model creation | HORIBA MIRA |

| Prediction of performance and emissions | HORIBA MIRA |

A high-level overview of the Empirical Digital Twin creation and validation process. This process can be added to the end of a verification or pre-certification test

The precision and reliability inherent in Empirical Digital Twins allow them to serve as a comprehensive repository of data, documenting every simulated scenario from performance metrics to safety evaluations. They help streamline the verification and validation process as well as equip legal teams with a wealth of information to be used as compelling evidence.

Consequently, the deployment of this technology empowers OEMs to navigate legal complexities with confidence and reduce uncertainty.

The integration of Empirical Digital Twins within OEM legal departments serves as a paramount strategy for bolstering reassurance and mitigating business risk. With the ability to predict and simulate all conceivable vehicle use cases, these digital tools provide an invaluable layer of foresight and evidence. Legal departments can leverage this technology as a proactive measure, offering a robust foundation for regulatory compliance and potential future litigation.

Based on previous experience, this methodology can reduce equivalent physical testing times by 70% for single vehicle and can help identify hotspots – rapidly identify unfavourable scenarios of vehicle performance and emissions that can result in non-compliance.

The creation of an Empirical Digital Twin of a powertrain using STARS Test Automation and STARS Enterprise software can have a transformative impact on vehicle testing. By combining real-world testing with advanced simulation capabilities, automotive companies can achieve unparalleled accuracy, efficiency, and innovation in their powertrain development processes.

Our case study demonstrates the seamless integration of our software in creating a powerful Empirical Digital Twin of a powertrain. This innovative approach not only ensures unparalleled accuracy in simulation but also empowers automotive companies to streamline development processes, reduce risk, and achieve new levels of excellence in powertrain optimization.

Fill out the form below to schedule a demo to learn how our Intelligent Lab software solutions can help your team.

Do you have any questions or requests? Use this form to contact our specialists.