Carbon dioxide is used in many kinds of industries, especially in food and beverage industry to produce carbonated drinks. Carbon dioxide is usually obtained as a by-product from ammonia synthesis. Other important source of carbon dioxide includes fermentation process in brewery. In these industries, customer faces challenge of possible contaminants due to different feed sources used to produce pure carbon dioxide.

In the beverage manufacturing process, the addition of external odor components and/or the changes in the balance of the flavors can generate odors called “off-flavors”, which degrade the quality of the product by impairing its taste.

In the case of beer, brewing is a complex fermentation process. It differs from other industrial fermentation processes, because flavor, color, aroma, clarity, foam associates with the finished product. Off-flavors could develop during the normal fermentation process but could also originate from impurities in carbon dioxide injected. The representative of problematic off-flavors is hydrogen sulfide (H2S) generated during the fermentation process. To minimize its generation in the manufacturing process the selection of fermentation conditions and yeast strains are controlled. Table 1 below shows the standard for beverage grade carbon dioxide (prepared with reference to European Industrial Gases Association (EIGA) documents). The purity of carbon dioxide required is 99.9%, total sulfur impurities is maximum 0.1 ppm.

The generally used method for off-flavor species analysis is manual sampling for gas analysis by chromatography in the laboratory. There is a need for online monitoring of sulfide off-flavors for quicker detection of contamination and improved quality control of final products.

Table 1: Standard of CO₂ purity limits for beverage (Prepared with reference to EIGA documents)

Carbon dioxide (later, CO2) for food and beverage industry is produced in two different ways. For carbonated soft drinks such as coke, it is produced as by-product of ammonia synthesis process in petrochemical plant. Then, CO2 is purified in gas manufacturer’s purification plant, and finally sold to beverage manufacturers.

Figure 1: Production process of carbon dioxide as by-product from petrochemical plants

For brewery, carbon dioxide is produced as by-product during the yeast fermentation process. Breweries prevent CO2 from going into the atmosphere by utilizing the gas for their products.

Figure 2: Production process of carbon dioxide as by-product from fermentation in breweries

Sulfur, or hydrogen sulfide, is a gas that has a characteristic foul odor of rotten eggs, which can lead to bad smell and bad taste of beverages. CO2 that is produced from fermentation process in brewery or from ammonia synthesis process in petrochemical plant have small amount of hydrogen sulfide.

For example, brewery (beer manufacturer) have fermentation process in their production line, where beer is manufactured from malt, hop, water and yeast. The yeast creates fermentation, where sugar (dextrose) breaks down into ethanol and CO2 in the absence of oxygen.

C6H12O6 (dextrose) → 2C2H5OH (ethanol) + 2CO2 (carbon dioxide)

In the fermentation process, yeast consumes sugar and expels a large amount of CO2 which can be “reclaimed” and used for beer. Unfortunately, during fermentation process, it also produces toxic, odorous sulfides which can foam up into the piping and contaminate the reclaimed CO2. In order to continue using the reclaimed CO2 byproduct but avoid the contamination of bottled beer with foul-smelling toxins, the reclaimed gas is run through deodorizing process shown in the Figure 3 below. However, sulfide breakthrough can occur if the CO2 gas did not spend enough time in the scrubber. Employees are sometimes tasked with sniff-testing of the reclaimed CO2, but this is an unhealthy practice and is very discrete to vigilantly prevent product contamination.

Another practice is batch measurement with gas chromatography conducted in the lab, but it will never give real time data, consequently it might be very hard to find out the contamination problem quickly. Finally, batch measurement is very expensive and contaminated CO2, which exceeds purity standards is simply sold cheaply or dumped.

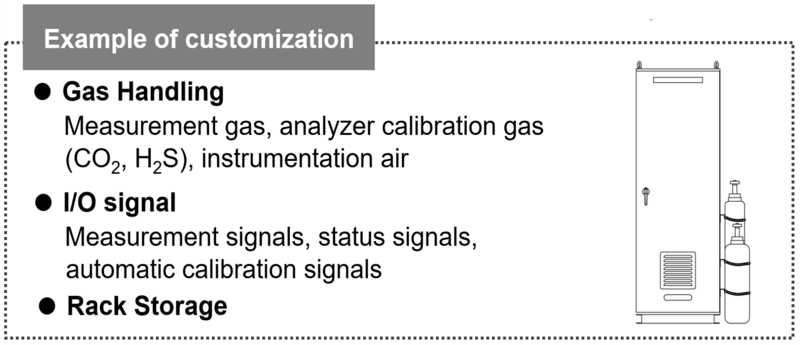

Continuous monitoring is a very cost-efficient solution, as it can immediately prevent the use of contaminated CO2 in bottling beer as well as provide feedback to process control engineers for the processing time of sulfur removal. HORIBA can provide sulfide analyzer in CO2 base gas as a continuous monitoring solution to prevent sulfide contamination in brewery products.

Figure 3: The process of CO₂ reclaiming in brewery

Gases associated with sulfide off-flavors can be measured as hydrogen sulfide with high sensitivity

Highly sensitive measurement of sulfide off-flavors after oxidation in the analyzer (0-10 ppb).

*Please contact us for sulfide off-flavors to be measured.

On-site maintenance schedules can be set up in advance according to any desired date and time, allowing for efficient calibration.

Multiple sampling points can be switched for measurement.

[High Sensitivity] Sulfide Off-Flavor Monitor APSA-370 with special converter CU-1

Table 2 : Specifications of APSA-370+Special CU-1

Carbon dioxide quality control along with off-flavors!

Carbon dioxide gas (CO2) analyzer for beverages VA-5001R

Multi-Component Gas Analyzer

Ambient Hydrogen Sulfide Monitor

Do you have any questions or requests? Use this form to contact our specialists.

![[High Sensitivity] Sulfide Off-Flavor Monitor APSA-370 with special converter CU-1 [High Sensitivity] Sulfide Off-Flavor Monitor APSA-370 with special converter CU-1](http://static.horiba.com/fileadmin/Horiba/_processed_/5/9/csm_APSA-370_CU-1_picture_04_4449e61d50.jpg)