Empirical Digital Twin

Create Simulation Models from Real Hardware

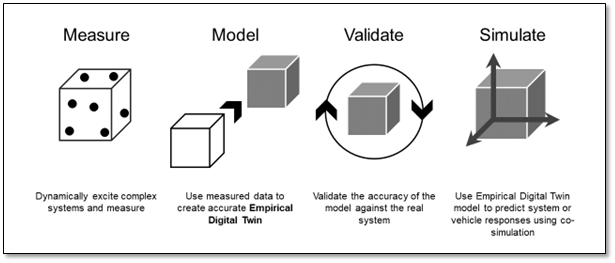

An accurate empirically derived digital twin model of a real powertrain can support a more optimized verification, validation and sign-off process.

Existing test automation systems and hardware can be used to follow a transient excitation cycle to simulate a non-linear system such as a hybrid powertrain. The benefit of this is that while some level of robustness can be achieved with traditional lab-based and in-field testing, a digital replica can be used to explore all possible scenarios thereby providing greater coverage and reduced risk.

Segment: Automotive

Division: Test Automation Systems

Manufacturing Company: HORIBA UK Limited

Base product:

Intelligent Lab