The Eyecon2 helps customers understand particle size and shape variation and in turn determine why a process is failing, why yield is reduced, what the source of product variation is, and whether or how a process can be best scaled up to commercial manufacturing.

Reduced cycle time, increased yields

- Tried and tested through installations around the world on Fluidised Bed Coating (e.g Wurster), Fluidised bed Granulation/Drying, Twin Screw Granulation, Dry Granulation/Roller Compaction, Extrusion Spheronisation, Milling, Blending, and product transfer process equipment.

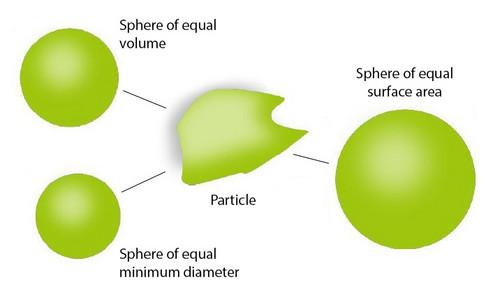

- Uses direct imaging processed in real-time, with ellipses fitted to each particle's boundary, shape and size reported back, highlighting variations.

- Continuous monitoring of processes critical quality attributes (CQAs) delivers sufficient understanding to devise a data-driven control strategy.

- Can be used both in-line and at-line/benchtop for at-line/benchtop measurement of manufacturing processes in real-time.

- Non-product contact to ensure proper measurements every time.

Testimonials

“The Glatt CPS® pelletization process requires a rapid objective PSD measurement method during processing to follow the particle growth curve and accurately determine end-point. Traditional methods are too slow or subjective and therefore may be an unacceptable risk for use as an In-Process Control (IPC) in a control strategy. Eyecon2 with its automated high-speed image analysis is implemented to accurately predict the process end-point with fast objective PSD data, supported by particle images, to significantly improve process optimisation and control.”

- Thomas Hofmaier, Head of Business Unit Process Technology Pharma, Glatt GmbH

“Before we had any PAT tools, process was like a black box to us. We put something in and get something out without knowing what happened inside. Now we have an ‘Eye’ to look inside that black box and see what’s really going on in there.”

“I believe the purpose of introducing a new technology should always be to get more returns out of it. When we introduce PAT technology, we hope to get better process understandings with it. And based on these understandings, we can work to get better product quality, higher yield or efficiency, which will eventually bring us very rewarding returns in time.”

- Deron HE, General Manager of Smart Manufacturing Dept., Chanse Technology (Jiangsu) Inc.

“More and more high-end Chinese pharmaceutical manufacturers are aware of and actively seeking to implement QbD principals into their manufacturing processes. Implementation of Eyecon2 optimises FBP design and subsequently enables increased process understanding.”

- Arthur Rong, Vice Manager, OSD, Austar