Stray light and the effect it has on Optical Signal to Noise ratio (S/N) falls into one of two major categories: a) random scatter from mirrors, gratings, etc., or b) directional stray light.

Stray light and the effect it has on Optical Signal to Noise ratio (S/N) falls into one of two major categories: Either a) random scatter from mirrors, gratings, etc., or b) directional stray light such as reflections, re-entry spectra, grating ghosts and grating generated focused stray light.

Consider first how much light there is to begin with at the primary wavelength of interest, then compare it to other wavelengths that may be present as scatter.

To determine the ratio of signal to noise, each of the components must first be quantified.

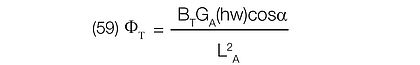

Flux entering the instrument (ΦT):

Ses = area of the entrance slit = (hw)

S’es = area of the exit slit = (h’w’)

BT = total radiance of light entering the instrument

GA = total illuminated area of the grating

Then from Equations (53), (50) and (51) total flux entering the instrument is given by:

However, there are many cases when the size of the image of the entrance slit is larger than the exit slit due to image aberrations. Light losses of this kind are “geometric losses” and may be characterized by the transmission through the system Tg.

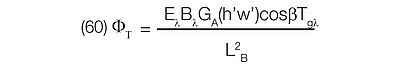

The flux at a given wavelength collected by the detector is given by:

where Tgλ is the geometric transmission at wavelength λ.

The luminance of randomly scattered light is proportional to the flux per unit area on the scattering optic. To calculate stray light due to random scatter:

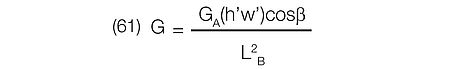

Let G = the etendue between the grating and the detector element.

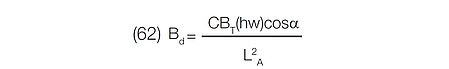

Let Bd = the radiance of stray light proportional to the total flux density ΦT / GA

C = a factor which expresses the quality of the optics (including the grating) as a function of random scatter.

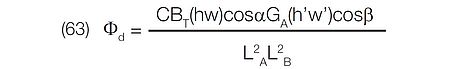

Total scattered flux is proportional to the radiance of the scattered light, to the area of the entrance slit, and the solid angle with which the exit slit perceives the illuminated optic. Random flux is given by: Φd = BdG

then,

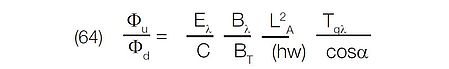

and the ratio of flux at the wavelength of interest Φu and the random flux Φd is:

Optimization requires two things: the maximization of (Φu/Φd) and the elimination of stray reflections. Taking the terms of Equation (63) in turn:

C: Obtain the highest quality optics including a holographic grating if one is available.

Eλ: Ensure that the grating is optimized to be most efficient at the wavelengths of interest.

L2A/(hw): Unfortunately, these may not be totally free parameters because of dispersion and bandpass requirements.

Tgλ: The dominant cause of image enlargement perpendicular to dispersion is astigmatism. If present, the height of the exit slit must be enlarged to collect all available light with subsequent loss in optical signal to noise ratio. New aberration correcting plane gratings for use in certain CZ spectrometers enhance S/N ratio by significantly reducing astigmatism.

Bλ/BT: This term is the ratio of the brightness at the wavelength of interest λ to the total brightness of the source; it is not usually a user accessible function.

This is an exercise in compromise. For example, take a researcher who owns a 500 mm focal length monochromator and is dissatisfied with the signal to noise ratio. Equation (64) suggests that S/N improvement may be achieved by utilizing a longer focal length instrument; a 1000 mm spectrometer just happens to be available. Assuming the bandpass requirement is constant for both experiments, the groove density, wavelength optimization, and size of the grating is the same, then throughput is halved (from Equation (52)). With all other things being equal, etendue will be proportional to the ratio of the focal length.

Optical S/N ratio would be improved by a factor of 2. Referring to Equation (64), the ratio of the squares of the focal lengths gives a factor of four and assuming the slit heights remain the same, the slit widths in the 1000 mm focal length system would produce double the area of the 500 mm system, thereby, losing a factor of two. The question to resolve is whether picking up a factor of 2 in S/N ratio is worth losing half the throughput. In this example, there may also be a reduction in the value of Tg, astigmatism being proportional to the numerical aperture (which in this case would be double that of the 500 mm system).

It is also worth checking the availability of a more sensitive detector. It is sometimes possible to obtain smaller detectors with greater sensitivity than larger ones. If this is the case, the total throughput loss may not be as severe.

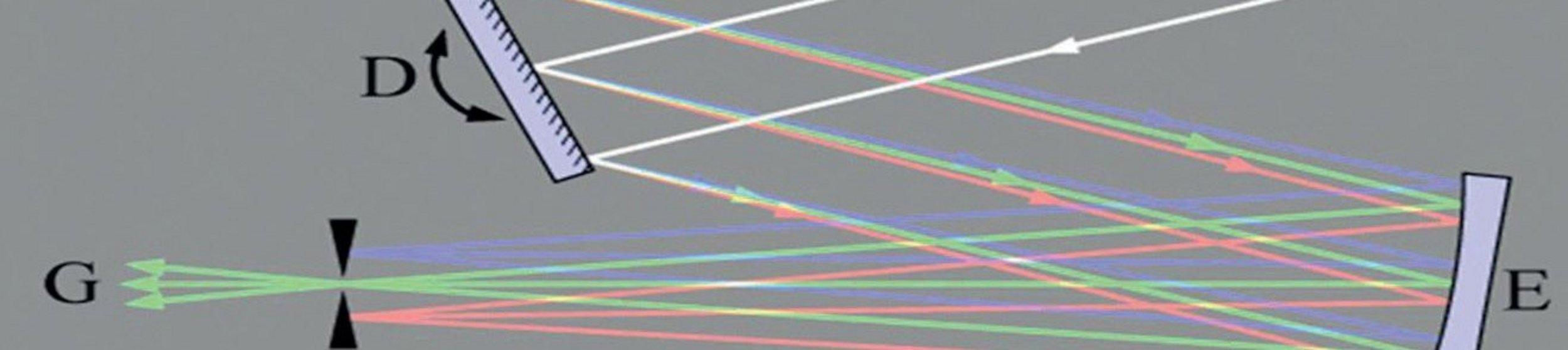

If the optics are overfilled, then a combination of stray reflections off mirror mounts, screw heads, fluorescence from anodized castings, etc. may be expected. The solution is simple: Optimize system etendue with well designed entrance optics and use field lenses to conjugate aperture stops (pupils). This is achieved by projecting an image of the aperture stop of the entrance optics via a “field” lens at the entrance slit onto the aperture stop of the spectrometer (usually the grating) and then image the grating onto the aperture stop of the exit optics with a field lens at the exit slit.

In some CZ monochromator configurations, a diffracted wavelength other than that on which the instrument is set may return to the collimating mirror and be reflected back to the grating where it may be rediffracted and find its way to the exit slit.

In some CZ monochromator configurations (especially thosewith low groove density gratings used in the VIS or UV), a diffracted wavelength other than that on which the instrument is set may return to the collimating mirror and be reflected back to the grating where it may be rediffracted and find its way to the exit slit. If this problem is serious, a good solution is to place a mask perpendicular to the grooves across the center of the grating. The mask should be the same height as the slits. If the precise wavelength is known, it is possible to calculate the exact impact point on the grating that the reflected wavelength hits. In this case the only masking necessary is at that point.

A more common example of this problem is found in many spectrometers (irrespective of type) when a linear or matrix array is used as the detector. Reflections back to the grating may be severe. The solution is to either tilt the array up to the point that resolution begins to degrade or if the system is being designed for the first time to work out of plane.

Classically ruled gratings exhibit ghosts and stray light that are focused in the dispersion plane and, therefore, cannot be remedied other than by obtaining a different grating that displays a cleaner performance. One of the best solutions is to employ an ion-etched blazed holographic grating that provides good efficiency at the wavelength of interest and no ghosts whatsoever. Any remaining stray light is randomly scattered and not focused.

This section reviews the effects of slit dimensions on S/N ratio for either a continuum or a monochromatic light source in single or double monochromator. It is assumed that the entrance and exit slit dimensions are matched.

Observation: S/N ratio does NOT vary as a function of slit width.

Explanation: From Equation (52), signal throughput increases as the square of the slit width (slit width determines the entrance etendue and the bandpass). Because the light source is a continuum, the increase in signal varies directly with both bandpass and etendue.

The “noise signal” also varies with the square of the slit widths as shown in Equation (63). Consequently, both the signal and the noise change in the same ratio.

Observation: S/N ratio varies inversely with slit height.

Explanation: Signal throughput varies linearly with slit height (from Equation (52)).

Noise, however, varies as the square of slit height (from Equation (63). Consequently, S/N ratio varies inversely with slit height.

Observation: S/N ratio varies inversely with slit width.

Explanation: Signal throughput varies directly with slit width (even though bandpass increases, only the etendue governs the number of photons available).

The “noise” is proportional to the square of the slit width. Consequently, S/N ratio is inversely proportional to the slit width.

Observation: S/N ratio varies inversely with slit height.

Explanation: Signal throughput varies linearly with slit height. Noise varies as the square of the slit height. Consequently, S/N ratio varies inversely with slit height.

Observation: S/N ratio varies inversely with slit width.

Explanation: S/N ratio at the exit of the first monochromator does not vary with slit width, however, the light now illuminating the optics of the second monochromator is approximately monochromatic and the S/N ratio will now vary inversely with slit width in the second monochromator.

Observation: S/N ratio varies as the inverse square of slit height.

Explanation: The S/N ratio varies linearly with slit height at theexit of the first monochromator. The second monochromator viewing "monochromatic" light will also change the S/N ratio inversely with slit height, therefore, the total variation in S/N ratio at the exit of the second monochromator will vary as the square of the slit height.

Observation: S/N ratio varies with the inverse square of the slit width.

Explanation: At the exit of the first monochromator S/N varies inversely with slit width. The second monochromator also illuminated by monochromatic light again changes the S/N ratio inversely with slit width. Consequently, the total change in S/N ratio is proportional to the inverse square of the slit width.

Observation: S/N ratio varies with the inverse square of slit height.

Explanation: Each of the two monochromators varies the S/N ratio inversely with slit height so the total variation in S/N ratio varies as the inverse square of the slit height.

Do you have any questions or requests? Use this form to contact our specialists.