Eco-Friendly Products

Development of Long-Life, Energy Conservation “Eco-Friendly Products”

In order to provide customers with products that reflect consideration of their life cycles, such as long those with usable lives and minimization of energy consumption, we have positioned certain products as “eco-friendly products” if they satisfy certain standards we have adopted; we use this description when developing and marketing such products. With social and economic matters such as rising energy costs in the background, we use quantitative measurement to determine to what extent products reduce energy requirements or materials used. With our “eco-friendly products,” we aim to achieve a 25% reduction compared to conventional models.

Example of Major Eco Design Themes

- Energy saving (reduction of standby power and power consumption)

- Resource saving (weight, packaging, types/number of parts used, amount of chemical substances used)

- Downsizing (weight, size, installation footprint)

- Noise reduction

Eco-friendly product: HORIBA, Ltd.

Infrared thermometer IT-270

Since its release in 1986, the "IT" series of infrared thermometer, which perform high-precision temperature measurement without touching the measurement object, have been used in various fields such as production, quality control, and research and development for more than 35 years.

Since its release in 1986, the "IT" series of infrared thermometer, which perform high-precision temperature measurement without touching the measurement object, have been used in various fields such as production, quality control, and research and development for more than 35 years.

"IT-270", while maintaining the industry-leading* accuracy, maximizes the use of core technology that is consistently performed in-house, from the development and production of key parts to the calibration of products.

*Results of 2021 in-house study

As for the “eco-friendly products”, the internal structure has been optimized to reduce the footprint by 62.8% compared to the previous model, realizing a smaller and more compact structure. It contributes to flexible layout design when incorporating into production line equipment in a wide range of industries, including semiconductors and aluminum.

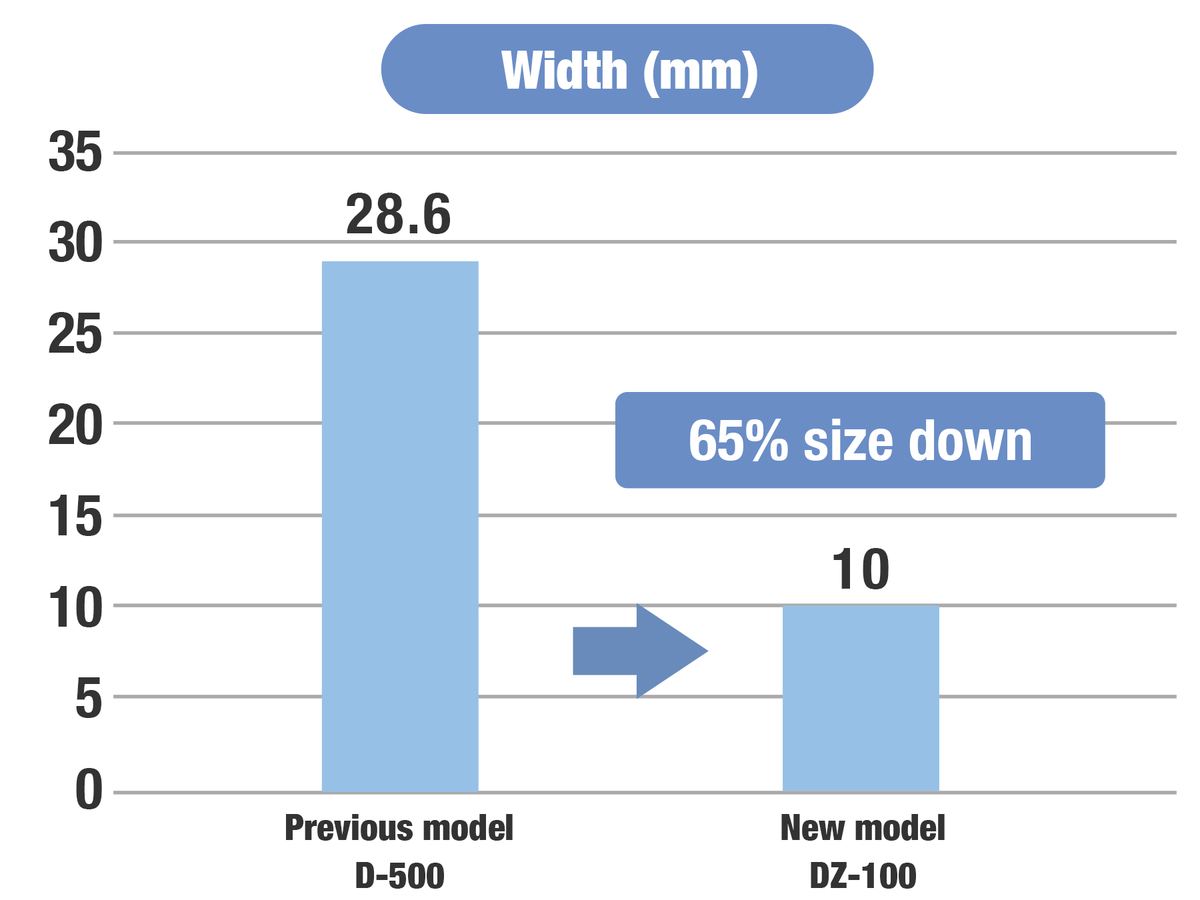

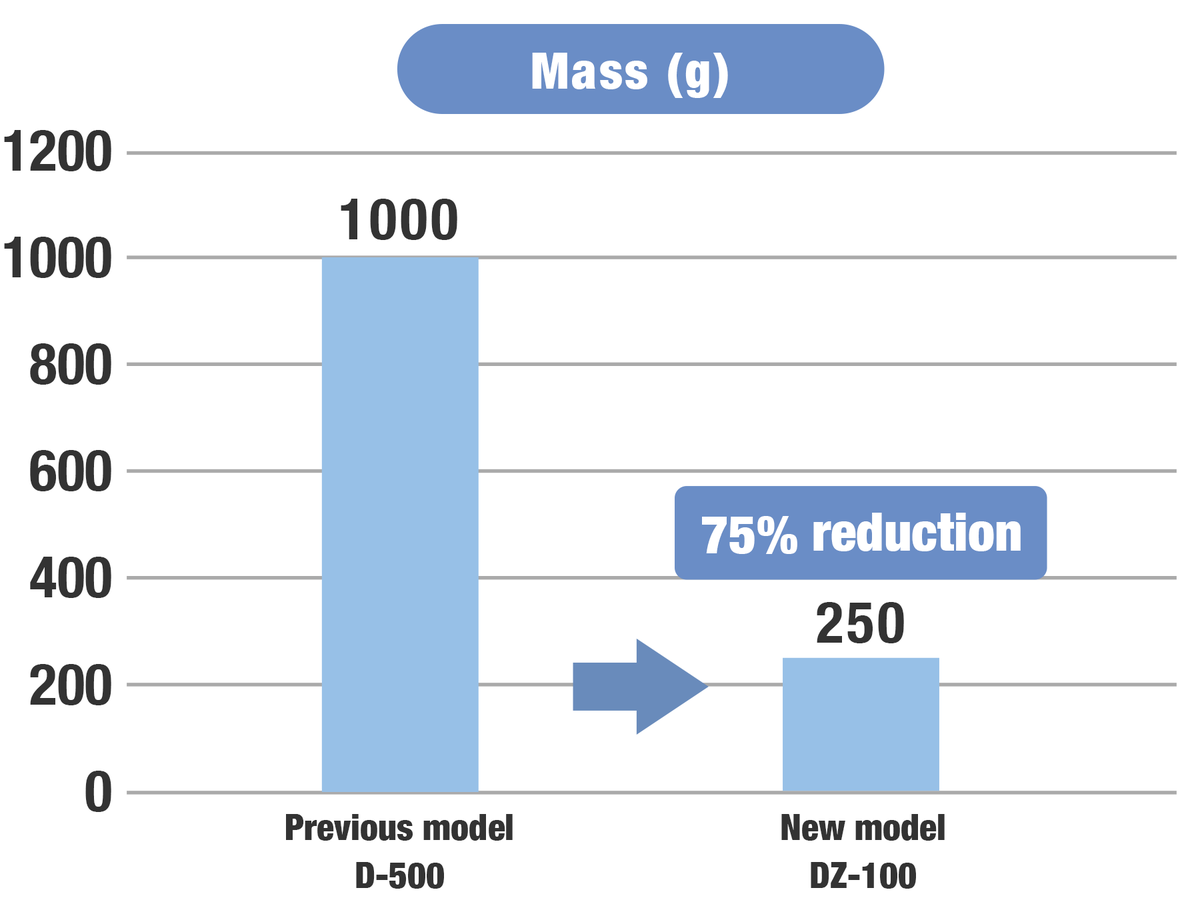

Eco-friendly product: HORIBA STEC, Co., Ltd.

CRITERION DZ-100 Series, Ultra-thin Mass Flow Controller

The ultra-thin DZ-100 Mass Flow Controller (MFC) with a width of 10 mm was developed for state-of-the-art manufacturing processes. This high-performance MFC contributes compact and light gas panels and multipath gas lines, both of which have been required at semiconductor production processes in recent years.

The DZ-100 was developed in response to the need for MFCs that retain the measuring principle and fluid control technology employed for existing models while containing numerous precision components, including sensors, in an ultra-thin body.

Accordingly, we set about developing element technologies for downsizing its body while maintaining the functionality of the existing models. We successfully reduced its product width to 10 mm, roughly a third of the existing width, without performance loss due to size reduction, and its weight was dropped by 75%. As a result of downsizing, we were able to lower resource consumption for materials of processed components, thus developing an eco-friendly product.

Eco-friendly product: HORIBA Advanced Techno Co., Ltd.

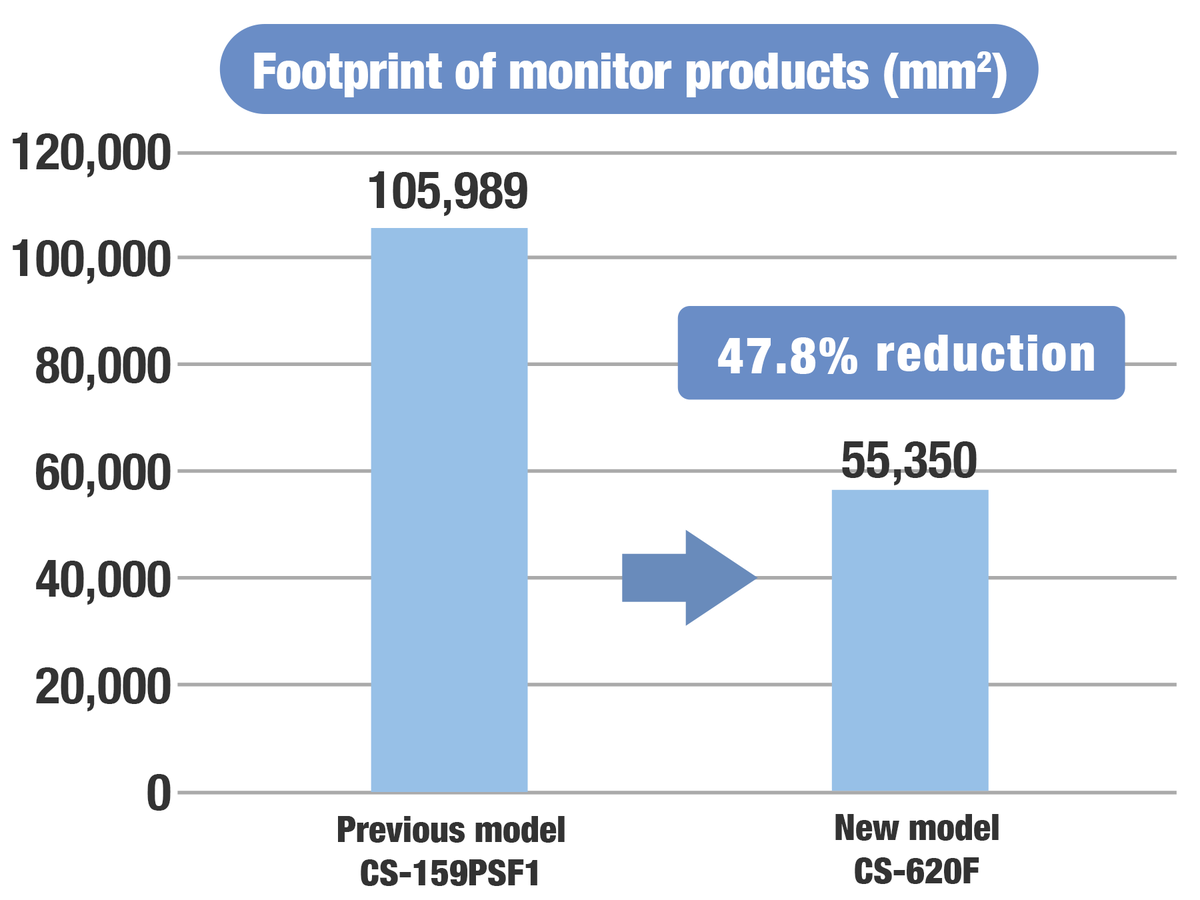

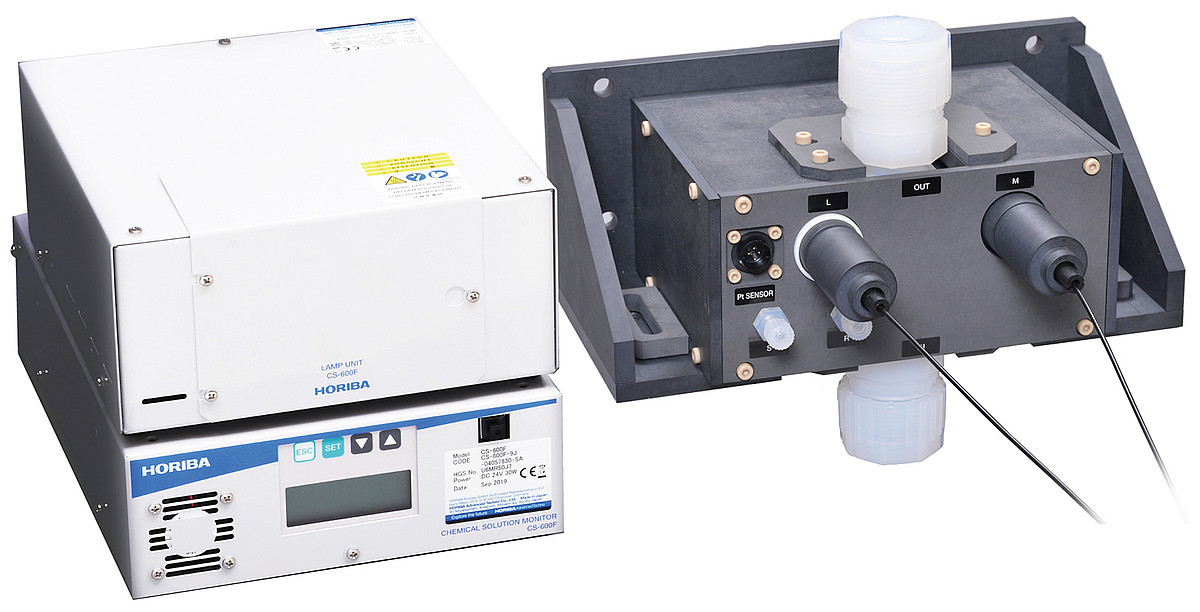

CS-620F, Fiber optic type hot phosphoric acid concentration monitor

The CS-620F monitors the concentration of phosphoric acids, which are used in the semiconductor manufacturing process, mainly in the three-dimensional NAND flash memory manufacturing process.

Previously, it was necessary to cool high-temperature phosphoric acids before measuring their concentration. By improving the sample measuring unit, the CS-620F gives real-time measurements of the concentration of a chemical solution without the need to cool it, while achieving reproducibility and stability equivalent to or higher than existing models. As this renders the cooling mechanism unnecessary, the monitor occupies less footprint within the unit.